What are the differences between Fuel Catalyst and Fuel Additives?

First the definition of a catalyst is a substance that increases the rate of a chemical reaction doing at a lower temperature or a higher energy level without itself undergoing any permanent chemical change. An additive is a substance added to something in small quantities to improve or preserve it.

What a Fuel Catalyst Is?

A combustion fuel catalyst is a type of technology developed to increase fuel efficiency and reduce emissions. These products can work in many ways by targeting the core problems behind incomplete combustion.

What a Fuel Additive Is?

A fuel additive are chemical substances that are added to gasoline, diesel, kerosene, and other fuels to impart or improve certain properties.

Why Fuel “catalyst” additives are not fuel catalysts?

Hybrid compound blend fuel additives are listed as “catalysts”, marketers use the word catalyst to promote products that are not real fuel catalysts. The substitution of the word’s additive, treatment, or supplement with the word catalyst is the origin of all the confusion.

A real fuel catalyst increases fuel efficiency and reduce emissions having a more complete and efficient combustion process without changing any fuel specification or properties.

Fuel “catalyst” additives are not real fuel catalysts. Additives and treatments serve completely different purposes than fuel catalysts, none of which are increasing fuel efficiency nor reducing emissions.

Fuel catalysts are not catalytic converters either, catalytic converters do not increase fuel efficiency, its purpose is to reduce emissions of all unburned hydrocarbons or partially burned out in the exhaust gases from an incomplete combustion process.

What is the Purpose of Fuel Additives and Treatments?

Fuel Additives and Treatments do not lower emissions or increase fuel efficiency like a real fuel catalyst, but additives and treatments do have benefits. All fuels burn inefficiently, at least to a degree. When fuels burn inefficiently, and they always do, hydrocarbon deposits buildup on the internal combustion components of an engine. Some fuels and additives are formulated to clean the hydrocarbon off the internal components of an engine.

One of the reasons fuel burns incompletely is because of a low octane rating. There are two manners in which fuels combust: exposure to a spark or flame and compression. If a fuel combusts before compression ratios of an engine, the result is a loss of power and knocking in a petroleum spark-ignition engine. Additives that increase the octane rating of a fuel increase engine efficiency and prevent damage.

The last type of engine additives/treatments are lubricants. Alcohol, ethanol, detergent additives and other high combustion rate additives refineries put in fuel can strip the natural lubricants inherent in diesel and petroleum from the internal components of an engine. This creates friction in an engine and leads to shorter engine life. Lubricant additives can help lower the friction rates of internal combustion and compression engines.

Why RENNSLI products are a real fuel catalyst

OurAdvanced Fuel Catalysts Technology ( RENNSLI, FEROX, 801 RACING ) modifies surfaces in both fuel particles and existing carbon deposits, this change reduces the combustion rate and temperature of the modified surfaces, making that resistant to burning components in the fuel may burn quicker and at lower temperatures than normally do.

The main active ingredients in our products are organo-metallic combustion catalysts, synergistic and multifunctional surface modifiers including combustion and hard carbon deposits surface modifiers.

Our products are non-flammable and can be used in any application or engine type, that use any type of liquid fuel from kerosene, gasoline, diesel, bunker, LPG, LNG without changing any fuel specification or properties.

This catalytic action works as a horsepower booster that brings more engine power and more power to the wheels with less effort, this will allow your engine to run at a lower temperature, more efficient and save fuel.

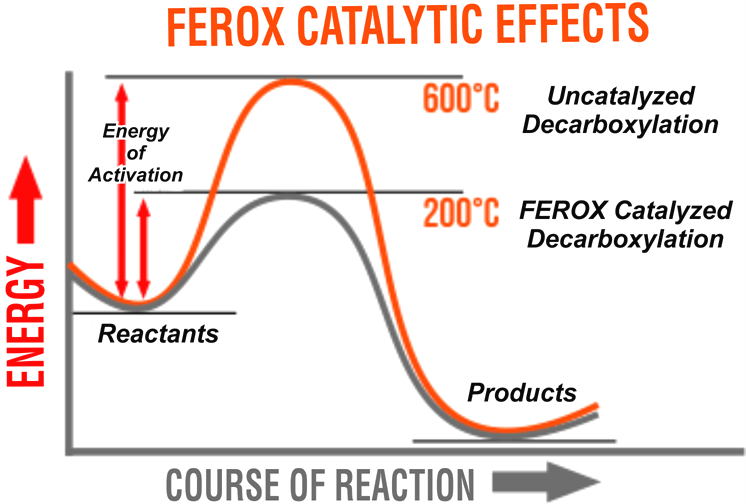

This graph illustrates the effect of fuel treated with catalyst FEROX against untreated fuel.

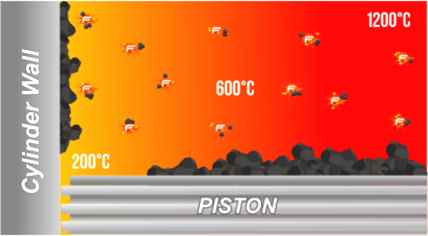

This graph shows the typical temperatures in the combustion chamber of an engine, looks like ferox molecules disperse and modify the activation temperature of the fuel and existing carbon deposits to achieve a complete and effective combustion.

Although rennsli products has produced fantastic results, in some cases the equipment, fuel, environmental factors and other conditions may vary enough to make it difficult to predict the magnitude of benefits in a specific application.

However, even when the initial effect is minimal, use continuously prevents the formation of deposits and performance degradation. The loss of efficiency costs, more downtime and loss of work associated with cleaning a dirty engine are generally much greater than the cost of using our products to maintain top efficiency over the life of the equipment.

There are two main forms of the fuel energy is wasted at the time of combustion, the first part of the fuel will not burn until it reaches the exhaust pipe and the second part of the fuel is never burned.

RENNSLI has developed a technology that works only on combustion to address these two problems.

Unburned hydrocarbons or partially burned out or form deposits in the exhaust gases along with other unwanted byproducts. In addition, some fuel continues to burn in the exhaust phase, causing loss of efficiency.

RENNSLI advanced fuel catalyst technology works in three ways, first burning existing carbon deposits, second prevents the formation of new deposits and third causes the fuel to burn more quickly so that their energy can be captured and used.

Removing carbon deposits and promoting a more complete combustion produces a variety of benefits:

- It increases mileage up to 20% or more in gasoline and up to 15% or more in diesel.

- Significantly reduces harmful emissions (CO, SOx, NOx, HC and PM10)

- Reduces the need to use higher octane fuel so you can start using regular gasoline immediately instead of Premium, with the same performance.

- It cleans the engines of carbon particles, main cause of the fault or malfunction of injectors and catalysts.

- Reduces engine wear by removing carbon and chamber deposits.

- Extends the life of the oil, spark plugs and filters.

- Our patented fuel tablets are completely dissolved in minutes without leaving residue.

After various third-party testing and user-led case studies, Rennsli Corp has been proven to save companies both time and money through increases in efficiency and preventative maintenance.

Recent Comments