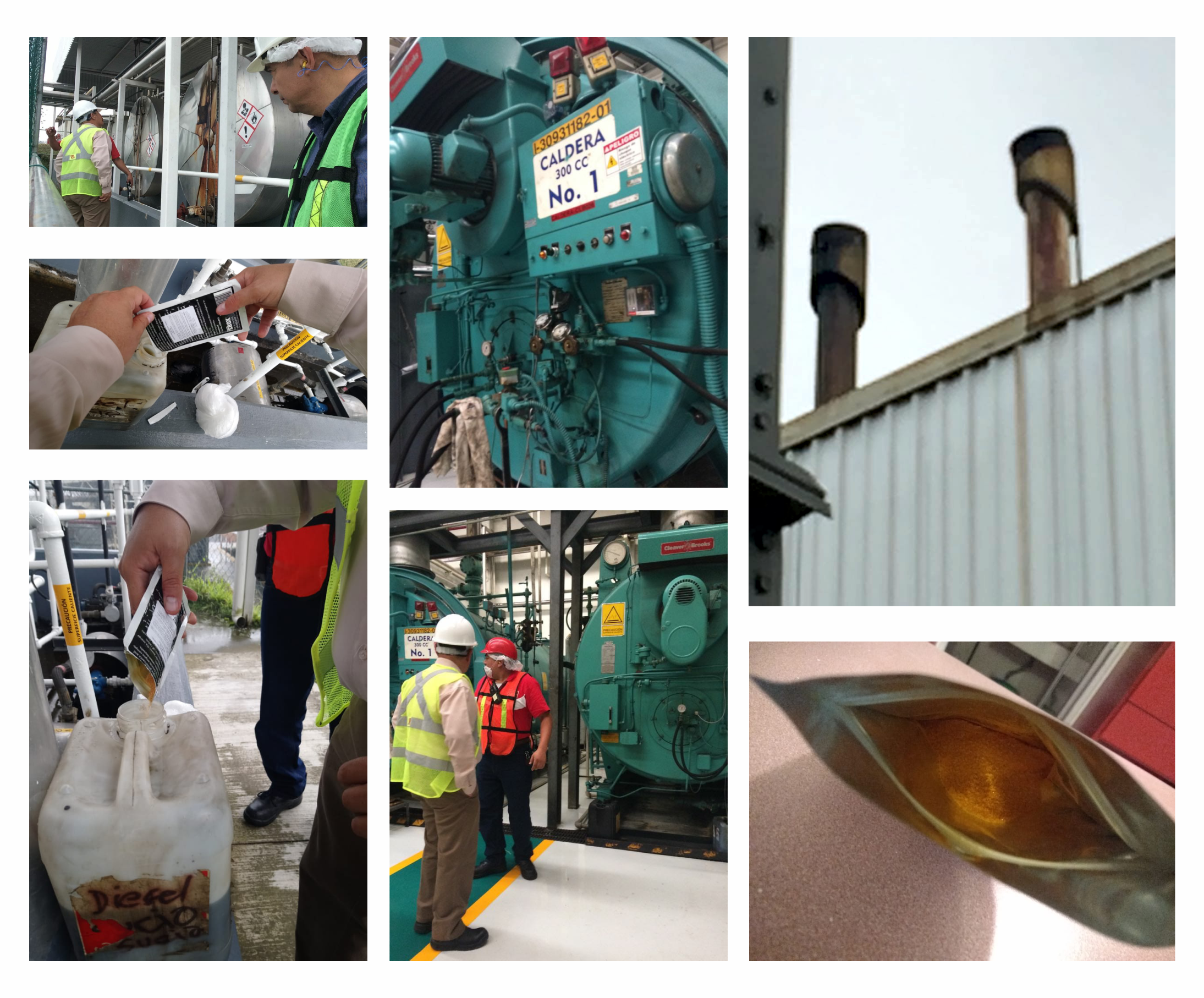

EFFECTS OF FEROX ADVANCED SOLID FUEL BORNE CATALYST IN OPEN FLAME APPLICATIONS BY RENNSLI ( FBC )

Open flame applications include: utility, industrial, commercial and institutional steam generators, process systems, kilns, and residential heating systems burning distillate or residual oil. The effects that Ferox has on the combustion process and byproducts of these fuels in open flame applications are summarized as follows:

The Ferox catalyst complex interacts with the heavier, long-chain, combustion resistant elements of the fuel and existing deposits in such a way that upon being burned or exposed to high temperatures, these elements are broken down and burned more easily. This “molecular atomization” of the fuel and destruction of surface deposits produces the following positive effects on the combustion process:

Quicker, more complete combustion.

Better use of available oxygen.

Lower excess air requirements.

Increased flame and temperature control.

Removal of existing deposits

Better heat transfer.

Lower fuel consumption.

Increased overall efficiency.

The effects on the combustion byproducts are a direct result of the changes in the combustion process. Ferox enhanced combustion produces the following positive effects on the byproducts of combustion:

Inhibition of new deposit formation.

Decreased particulate, smoke, and soot formation.

Decreased NOX, SOX, CO, and VOC emissions.

Increased ash capture potential of SO2.

Decreased carbon content in the ash.

Decreased fouling and corrosion due to decreased V2O5 activity.

Decreased cold end corrosion due to decreased SO3 formation.

For more information click the links to see our Technical Bulletins:

Don’t take our word for it though, give it a try!

Contact us to order some of our revolutionary solid-fuel technology with over 30 years of research and development. It works in everything from your compact car to tier-4 equipment.

Recent Comments